The technology that revolutionizes the cleaning of Reusable Medical Devices

UNI EN 556 international Standard states that it is not sufficient for an instrument to appear visually clean to guarantee the absence of surface residues.

BICARmed® technology ensures adequate cleaning of Reusable Medical Devices (RMD), an essential prerequisite for effective action of the subsequent disinfection and sterilization phases.

UNIQUE

One way to pre-washing all instruments: endoscopic optics, motor drills, canulas, fragile instruments, generic and specialized instruments.

SAFE

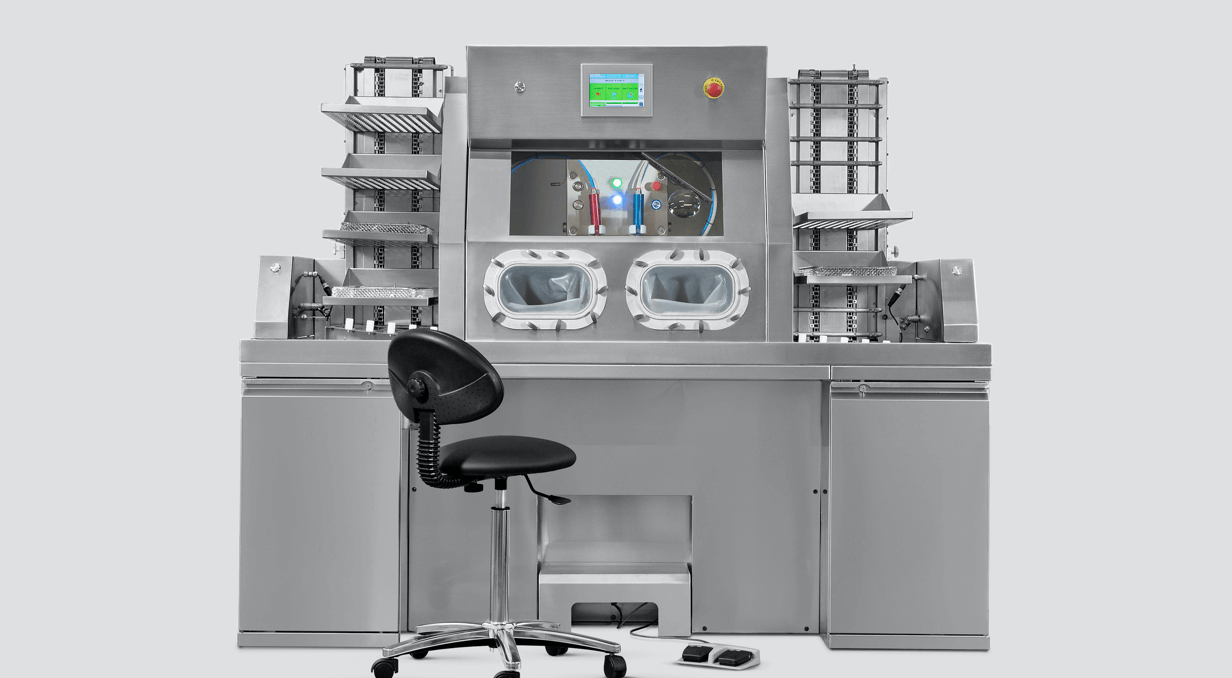

The treatment does not damage the protection of the instruments and is performed into a closed cabin thus avoiding operator contact with dangerous contaminants.

EFFECTIVE

Maximum removal of difficult compounds like dirt, bone, cements, cauterized blood, even on geometrically complex surfaces.

ECONOMICAL

Significant reduction on maintenance of RMDs costs. Wear prevention by oxidation, corrosion, pitting and biofilm.

Surgical instruments cleaning is important

Pre-washing phase is important because it removes the residues of organic and inorganic substances from the surfaces of medical devices.

An adequate cleaning:

- Drastically reduces microbial contamination (BIOBOURDEN)

- Improves the contact between the disinfectant / sterilizing agent and the infectious microorganisms left on the surfaces

- Guarantees instruments functionality and longevity

BICARmed® technology guarantees maximum effectiveness in cleaning all RMDs, even for the most critical washing challenges:

Critical tools to clean

- Tools with complex shapes and geometries as:

-

- Endoscopic tools

- Cannulated tools

- Orthopedic tools

- Electrosurgery tools

- Delicate microsurgery tools

- Robotic tools

- Rigid optics

- Not-submersible tools

Critical dirt

- Heavy dirt

- Dry dirt

- Residues from cauterization practices

- Inorganic residues

- Glue residues

- Cement residues

- Bone residues

Cleaning process

TRADITIONAL

Pre-wash MANUAL, ULTRASOUND E/O OTHER

WASHER DISINFECTOR

Clean tools

42,1%Cleaning process

BICARmed®

Pre-wash

WASHER DISINFECTOR

Clean tools

98,2%Effectiveness in

comparison

RMDs are often characterized by significant differences concerning geometry, materials, structure, resistance to reconditioning, initial contamination degree and level of reconditioning for use. In case of difficult instruments to clean and adhering contaminants, traditional washing processes may be insufficient and it is necessary to resort to manual pre-washing remedies harmful to the devices and dangerous for the operators (brushing, solvents, treatments with abrasive pastes, air – steam) not always effective.

BICARmed® technology guarantees maximum effectiveness on all instruments and dirt types, ensuring homogeneity of the result and maximum contaminants removal. The two tables illustrate the test results conducted according to Annex N of standard ISO / TS 15883-5a on five RMDs (Poole suction tube, micro-invasive forceps core, micro-invasive forceps handle, trocar, hemostatic forceps) respectively with traditional cleaning methods and with BICARmed® solution. BICARmed® technology, with 98% effectiveness, results significantly more efficient and safer than the methods currently in use.

Read moreCleaning: first phase of BICARmed®reprocessing.

BICARmed®, the cleaning that improves performances

Process of reconditioning the RMDs is the set of activities necessary for dirt removal and reduction of the microbial load on a device after its use until the reaching of sterility conditions required for a new use.

Each single phase of whole process contributes to improve the effectiveness of subsequent phase: it is enough not to guarantee just one of these phases to compromise the whole process and expose the patient, the operator and the Company to potential risks.

The proper cleaning of Reusable Medical Devices (RMD) is therefore an essential prerequisite for an effective action of the subsequent disinfection and sterilization phases.

BICARmed® technology occurs here, at the beginning of the reconditioning process, in the dirty area.

BICARmed® revolutionizes the RMD cleaning notion because the treatment can be carried out, with the same effectiveness, on all instruments typologies, in order to remove even the most difficult dirt, significantly increasing the whole process performances.

Read more about our solutions

You can clean without sterilizing, but you can not sterilize without cleaning.