Non abrasivity

Non-abrasivity test of sodium bicarbonate on metals

Trento University - Materials engineering department

Methodology and tested materials

In the study done by Trento University, summarized in the table below, several steel and aluminum samples were subjected to the BICARJET® cleaning treatment with sodium bicarbonate. Distance for all treatments was kept constant at 7cm. Treatments were all carried out keeping the jet perpendicular to the sample. Bicarbonate grain size was kept constant at 400 microns.

| STEEL | HARDNESS (Vickers) | PRESSURE (bar) | TIME (seconds) |

|---|---|---|---|

| C45

C45 milled 2312 2312 milled |

196 HV 196 HV 287 HV 287 HV |

1 3 5 |

15 15 15 |

| TEMPERED

IMPAX ORVAR STAVAX |

296 HV

311 HV 489 HV 556 HV |

1 2 3 |

15.30 15.30 15.30 |

| ALUMINUM | HARDNESS (Vickers) | PRESSURE (bar) | TIME (seconds) |

|---|---|---|---|

| AL mold | 185 HV | 1 3 5 |

15.30 15.30 15.30 |

| AL ERGAL 55 polished (1° test) | 185 HV | 1 3 |

15,60 15 |

| AL ERGAL 55 polished (2° test) | 185 HV | 0,5 1 1,5 3 |

15 15 15 60 |

Results

They were made measurements of:- Vickers hardness before and after treatments – Wolpert hardness tester

- X-ray diffraction (microstructural analysis) – Rigaku Geigerflex diffractometer

- roughness measurement before and after the treatments- Profilometers Hommel Tester T8000-Hommelwerke GMHB and Tecnor mod.Alphastep200

- scanning electron microscopy (morphological analysis) – Microscope Philips XL30

- atomic force microscopy (morphological analysis) – AFM Burleigh mod. Vista

- weight loss after treatment – Scales with sensitivity of 10-6 grams

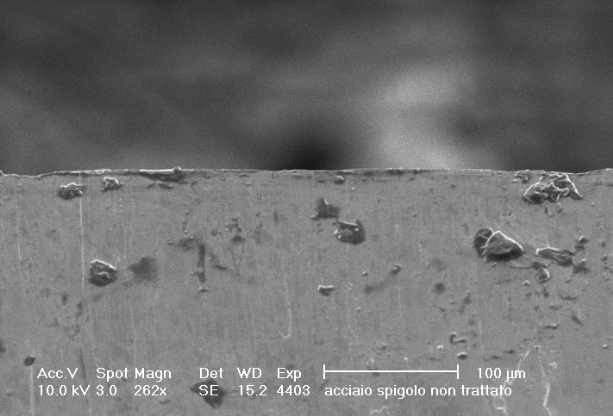

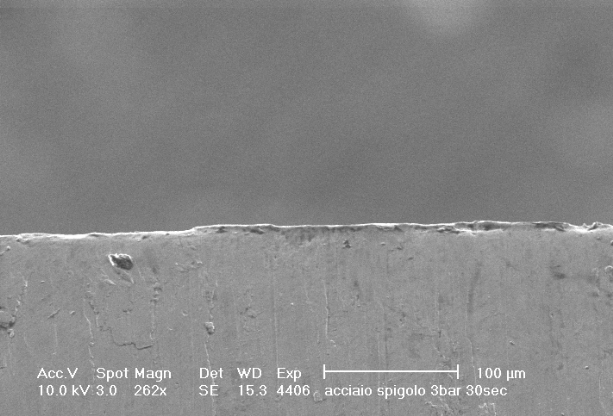

| COMPARISON BETWEEN THE EDGE MORPHOLOGY OF A STEEL AISI 304 in the untreated part (a) and treated 3 bar for 30 seconds (b). | |

|---|---|

(a)

(b)

|

|

Enlargement is 200 times and the bar indicates the distance equivalent to 100 micrometers.

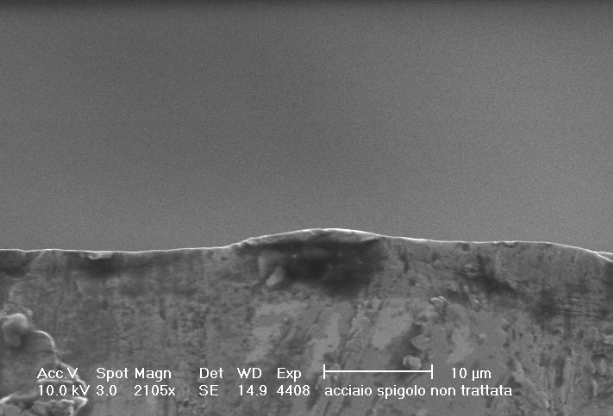

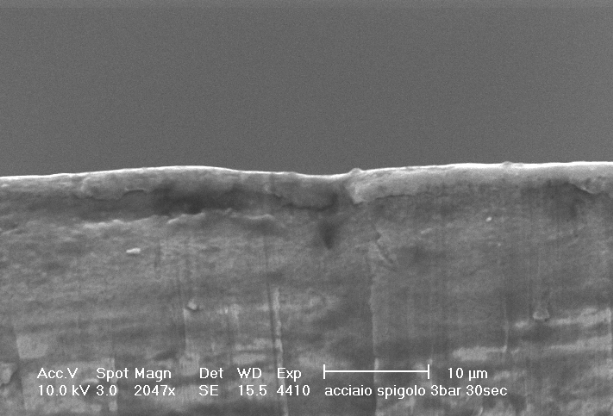

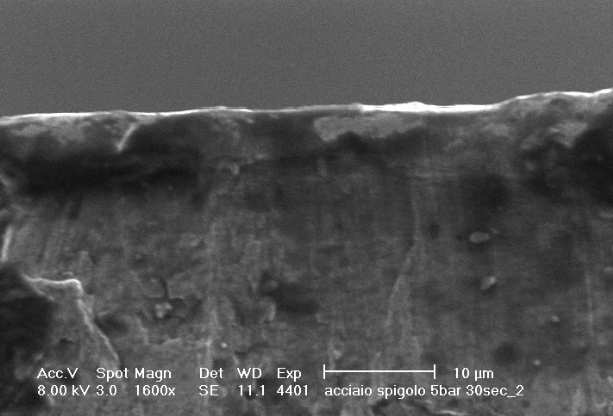

| COMPARISON BETWEEN THE EDGE MORPHOLOGY OF A STEEL AISI 304 in the untreated part (a); treated for 30 seconds at 3 bar (b) and at 5 bar (c). | |

|---|---|

(a)

(b)

(c)

|

|

Enlargement is greater than 1600 times and the bar indicates the distance equivalent to 10 micrometers.

Conclusions

Studies carried out on the selected samples have shown that the sodium bicarbonate treatment affects and modifies the metals only for thicknesses of a few micrometers, even at the highest pressures.

On samples with a hardness higher than 200-250 Vickers HV up to pressures up to 5 bar there are no appreciable roughness variations.

During the cleaning process there is no matter removal.

For samples with a hardness lower than 200 Vickers the behavior between steel and aluminum samples differs: steels, not very ductiles, continue to show no evident variations in roughness while the more ductile aluminum changes at treatment pressures higher than 1 bar. For pressures of 1 bar or less, the behavior of the aluminum samples is similar to that of steel, with effects of limited modification of the surface roughness which, in specific cases, decreases the brightness.